|

The Software designed for organizing data and providing the mechanism for storing, maintaining, and retrieving that data on a physical medium (i.e., a database). A DBMS separates data from the application programs and people who use the data and permits many different views of the data.

Reference: APICS Dictionary, 16th edition

0 Comments

An extreme change in the supply position upstream in a supply chain generated by a small change in demand downstream in the supply chain. Inventory can quickly move from being backordered to being excess. This is caused by the serial nature of communicating orders up the chain with the inherent transportation delays of moving product down the chain.

In the theory of constraints, the planned amount by which available capacity exceeds current productive capacity. This capacity provides protection from unplanned activities (such as resource contention) and preventive maintenance and unplanned activities (such as resource breakdown, poor quality, rework, or lateness). Safety capacity plus productive capacity plus excess capacity equals 100 percent of capacity.

The process of Measuring quality conformance by comparing the actual with a standard for the characteristic and taking corrective actions on the difference.

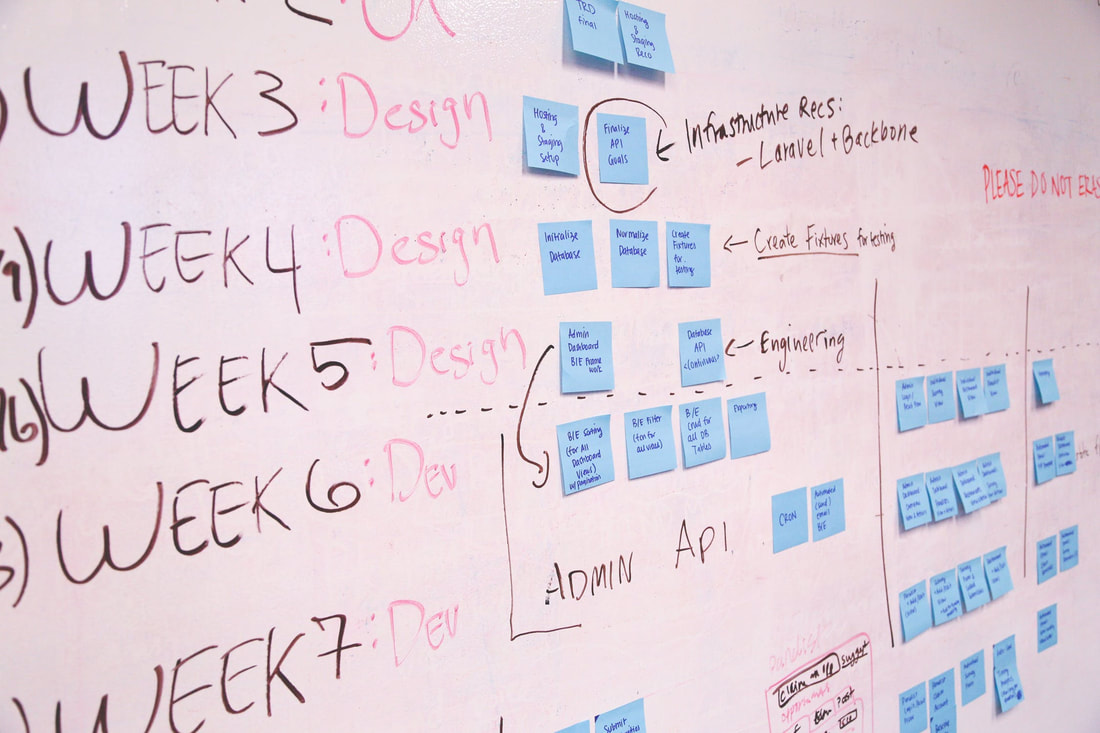

The APICS Dictionary, 15th edition, defines change management as follows: The business process that coordinates and monitors all changes to the business processes and applications operated by the business, as well as to its internal equipment, resources, operating systems, and procedures. The change management discipline is carried out in a way that minimizes the risk of problems that will affect the operating environment and service delivery to the users.

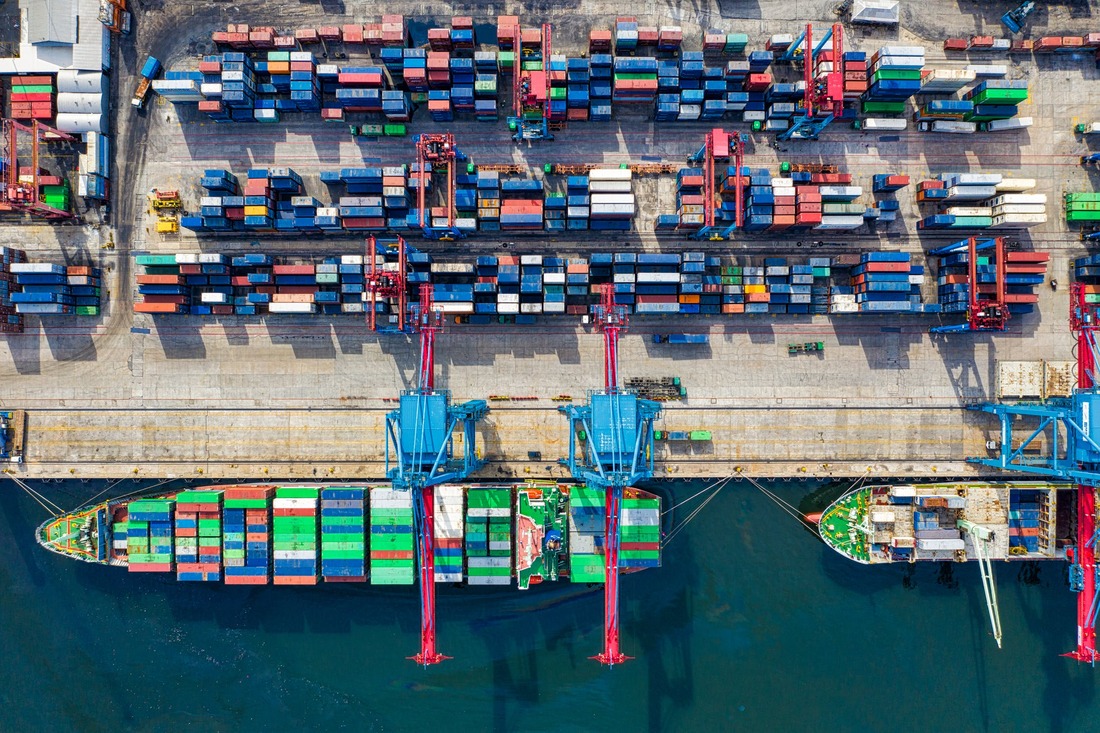

The function of determining the need to replenish inventory at branch warehouses. A time-phased order point approach is used where the planned orders at the branch warehouse level are “exploded” via MRP logic to become gross requirements of the supplying source. In the case of multilevel distribution networks, this explosion process can continue down through the various levels of regional warehouses (master warehouse, factory, warehouse, etc.) and become input to the master production schedule. Demand on the supplying sources is recognized as dependent and standard MRP logic applies.

The time unit for which forecasts are prepared, such as week, month, or quarter.

The use of skills and knowledge in coordinating the organizing planning, scheduling, directing, controlling, monitoring and evaluating of prescribed activities to ensure that the stated objectives of a project, manufactured good, or service are achieved.

Capacity planning conducted at the business plan level. The process of establishing, measuring, and adjusting limits or levels of long-range capacity. Resource planning is normally based on the production plan but may be driven by higher-level plans beyond the time horizon of the production plan (e.g., the business plan). It addresses those resources that take long periods of time to acquire. Resource planning decisions always require top management approval.

A dispatching rule that selects the job having the earliest due date for the impending operation. See: earliest due date.

|